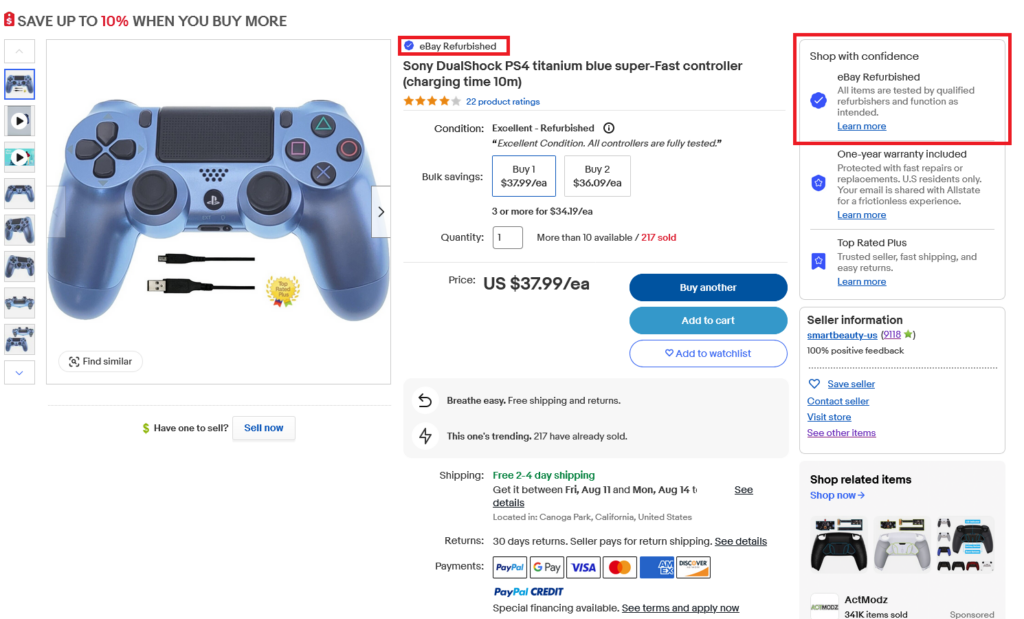

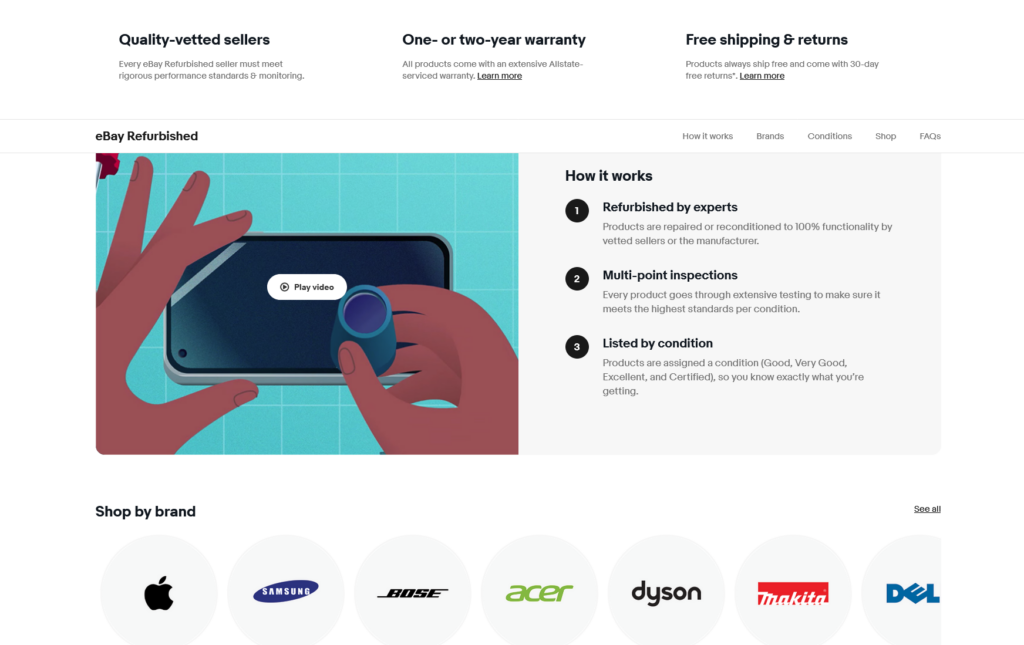

Counterfeits have always been a problem on eBay. But recently eBay launched a new program called “eBay Refurbished” through which select sellers can list “refurbished” items and get benefits like promoted listings and a shiny new badge that shows up in their listings. Here’s what eBay has to say about the program:

“Quality-vetted sellers”? “Refurbished by experts”? “Reconditioned to 100% functionality by vetted sellers or the manufacturer”? “Multi-point inspections”? Wow, this sure sounds like eBay have some stringent standards for the program. Surely, they’ll only grant the prestigious “eBay Refurbished” badge to the cream of the crop. They’d never use all that flowery language and then grant the badge to any ol’ Tom, Dick, or Harry who just wants to sell crap he ordered on Alibaba, would they?

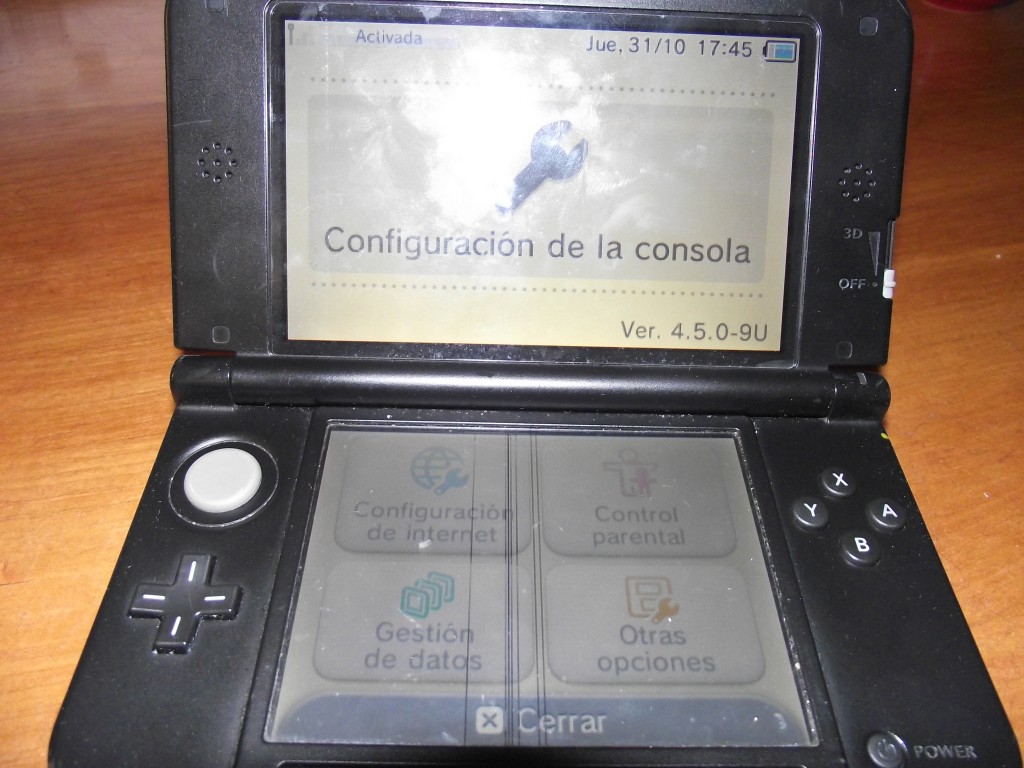

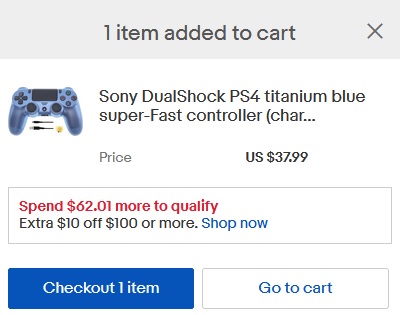

Let’s place an order. I wonder what we should buy

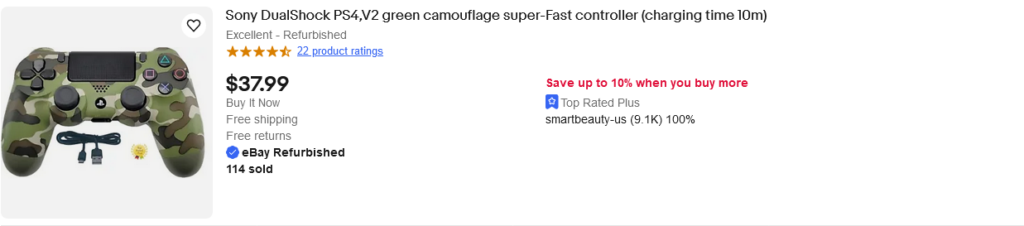

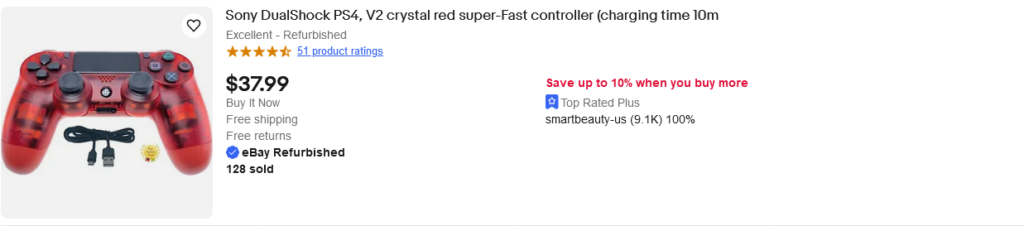

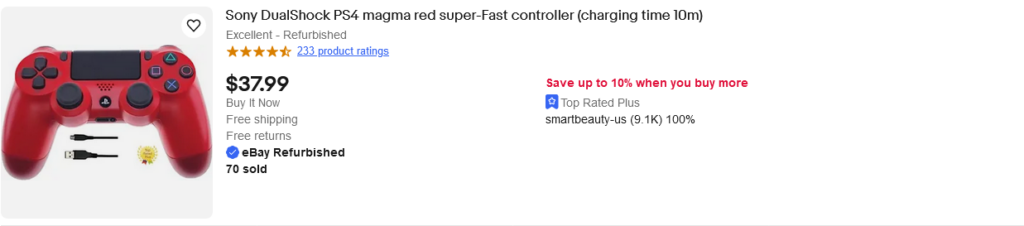

Wow, 112 crystal clear controllers sold? 232 red camo controllers sold? 432 purple controllers sold? This seller obviously has a ton of experience refurbishing Playstation 4 controllers. I have no qualms now that I see he’s sold thousands of them. Let’s buy a titanium blue one.

Now we just have to wait for it to arrive.

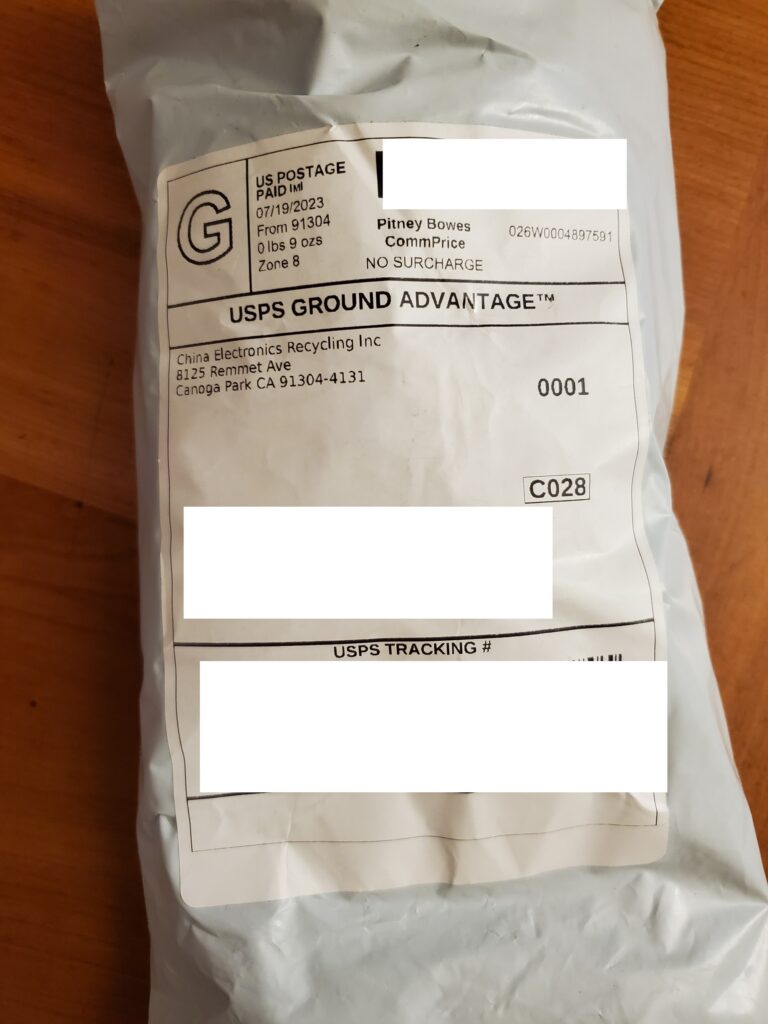

Okay it’s here.

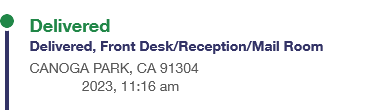

Hmm…. “China Electronics Recycling Inc”? Canoga Park, CA? Where have I seen this before?

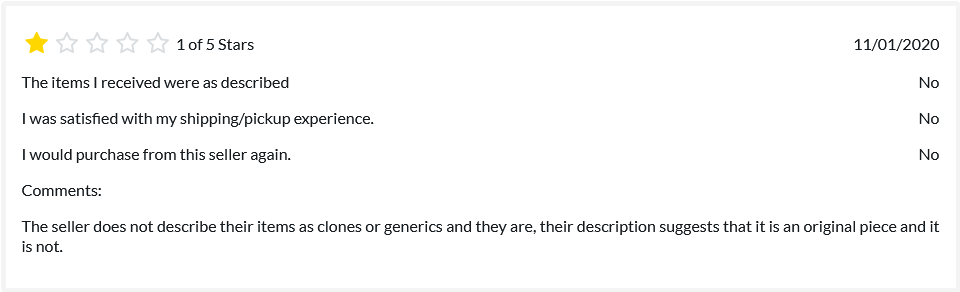

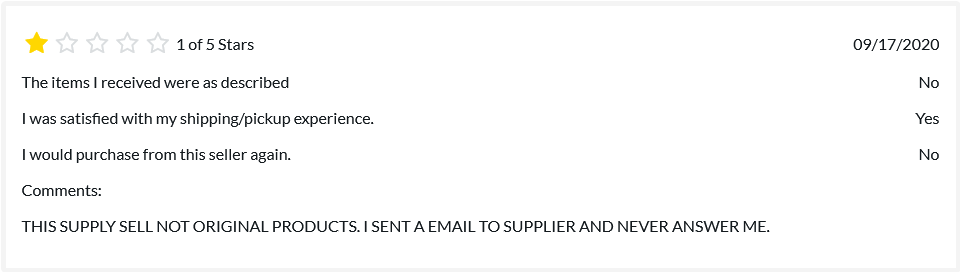

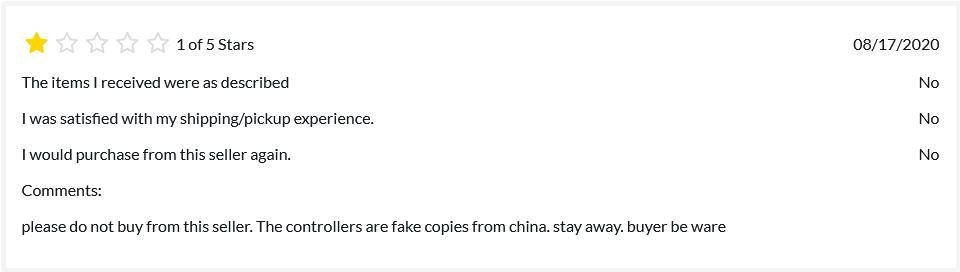

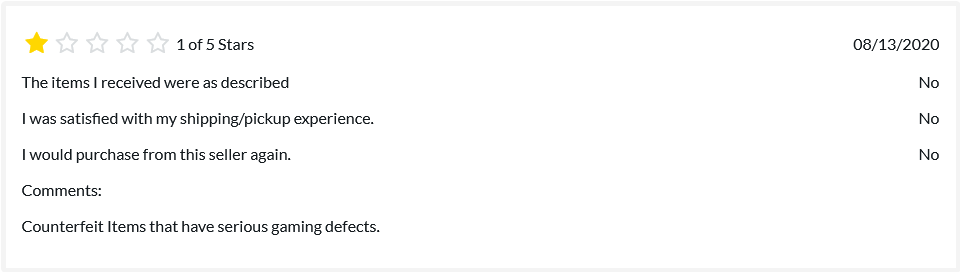

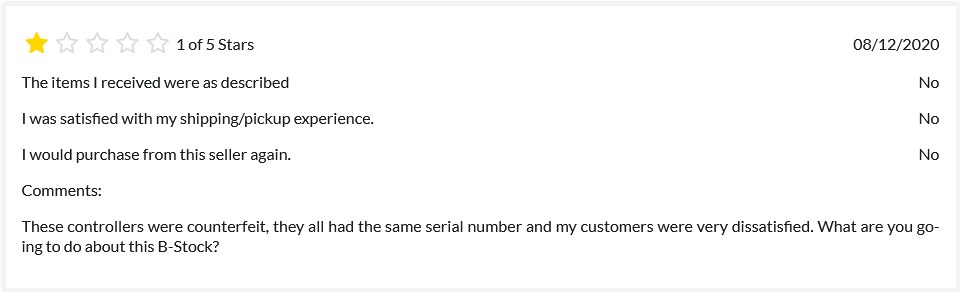

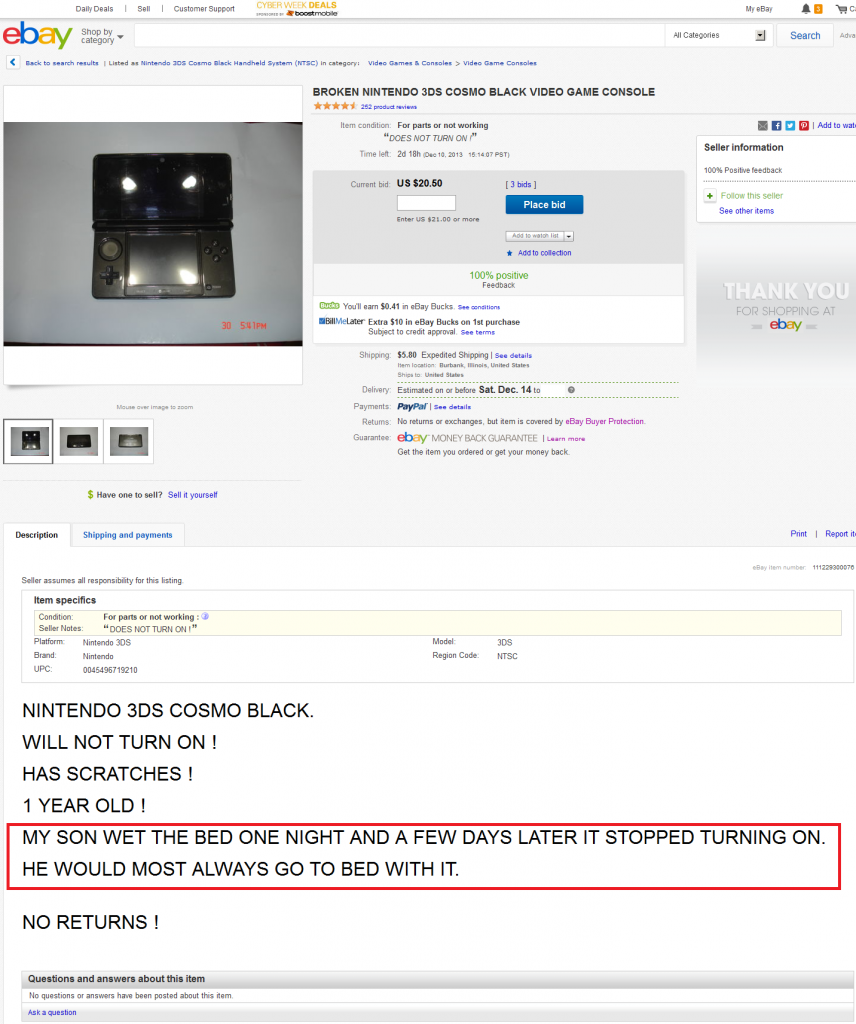

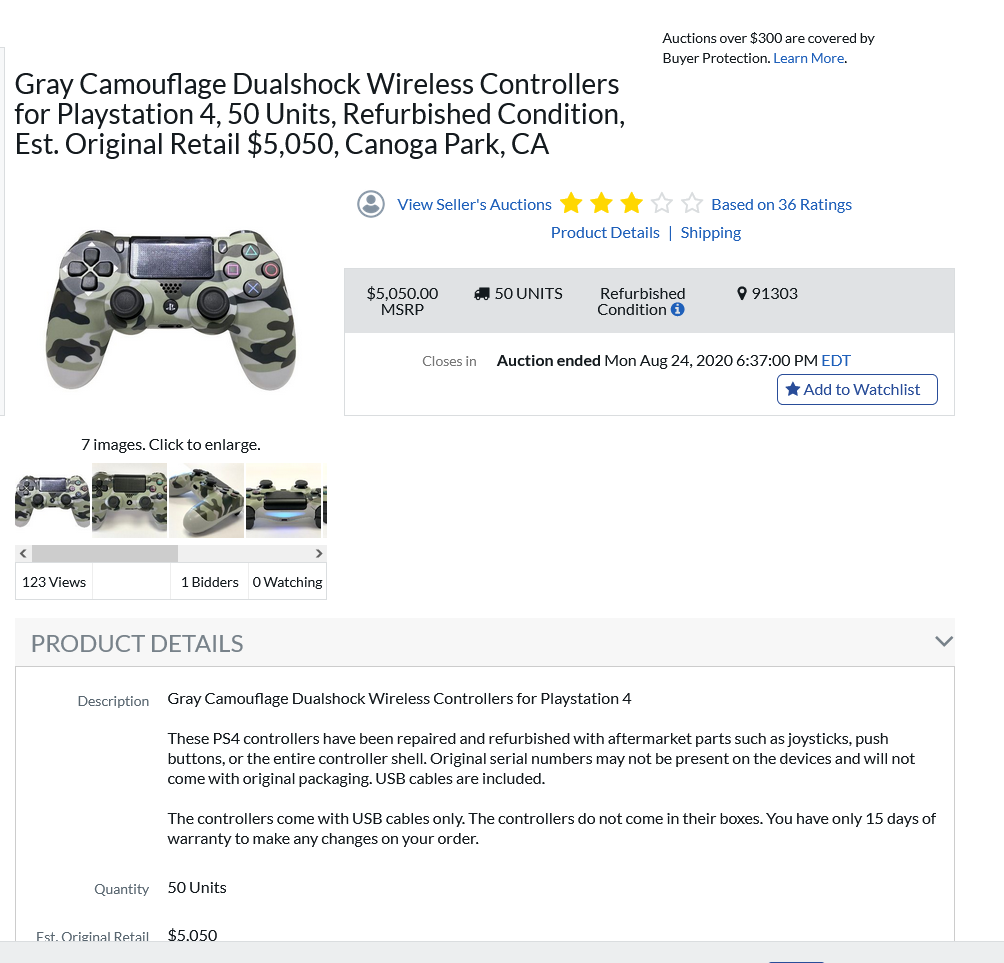

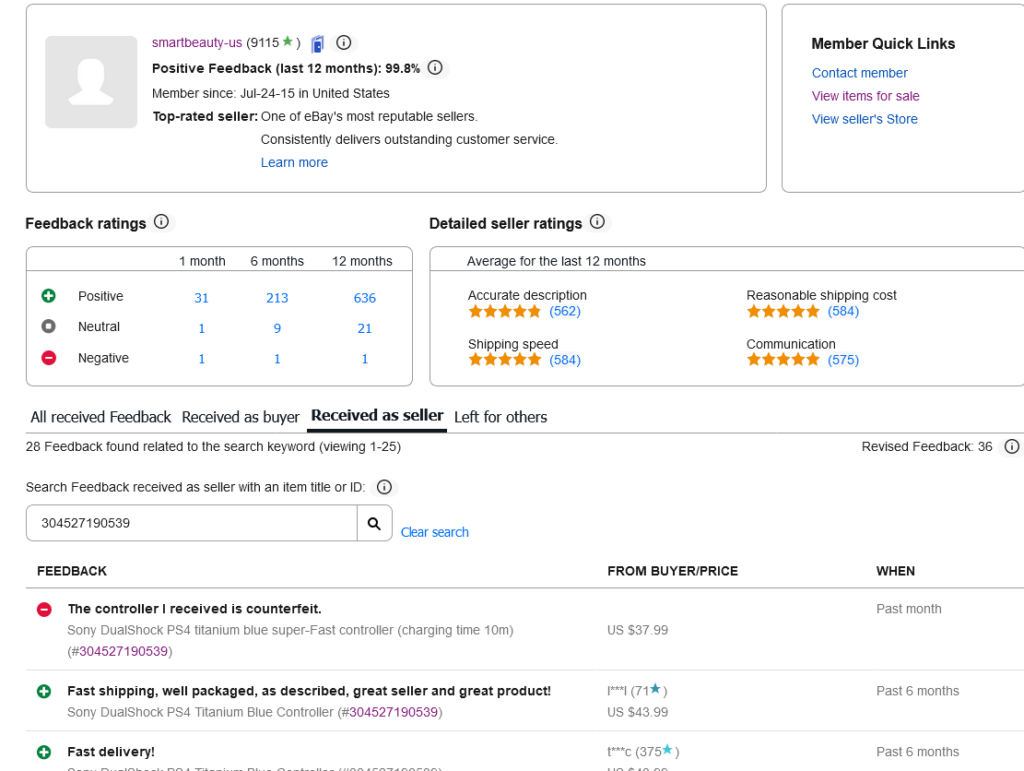

Oh, now I remember. It’s that seller who repeatedly listed lots of counterfeit PS4 controllers on B-stock supply, calling them “refurbished” instead. Don’t believe me that they were counterfeit? Here’s what just a few of that seller’s customers had to say:

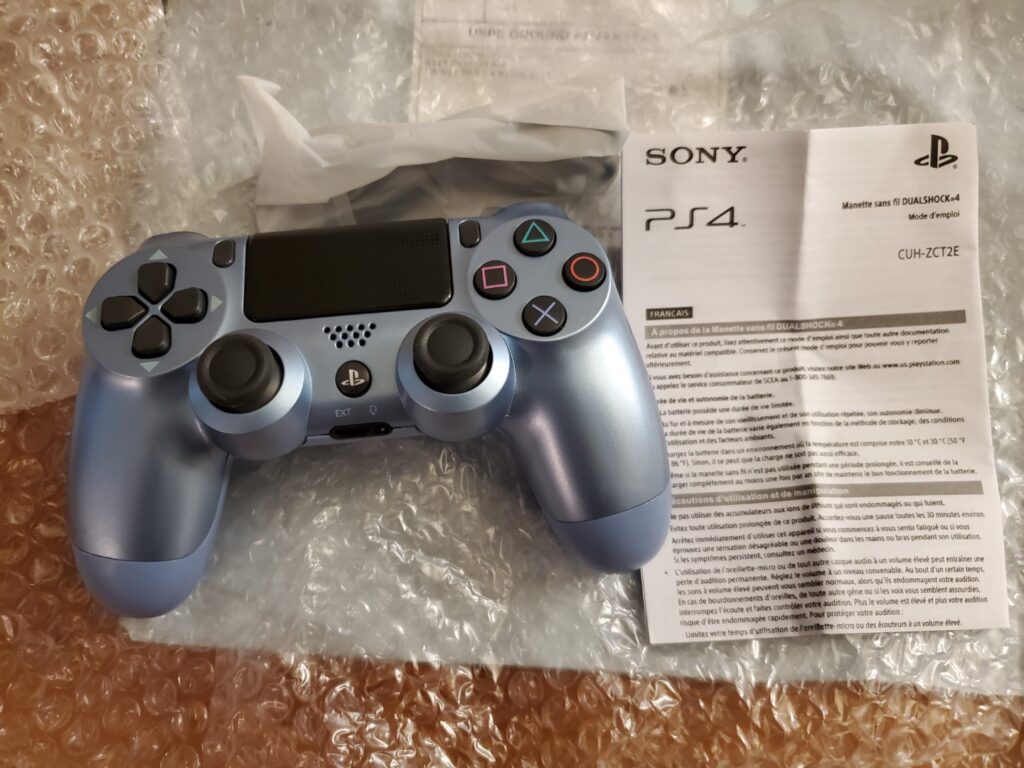

In any case, let’s open the package.

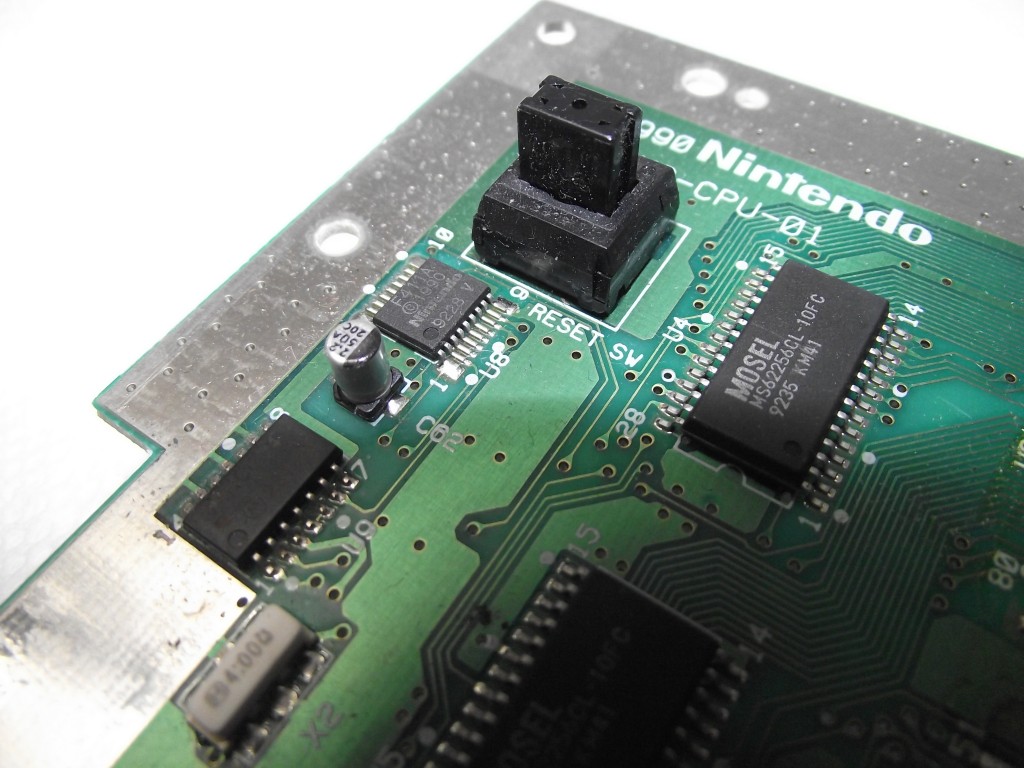

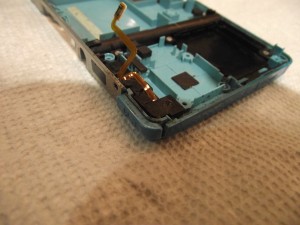

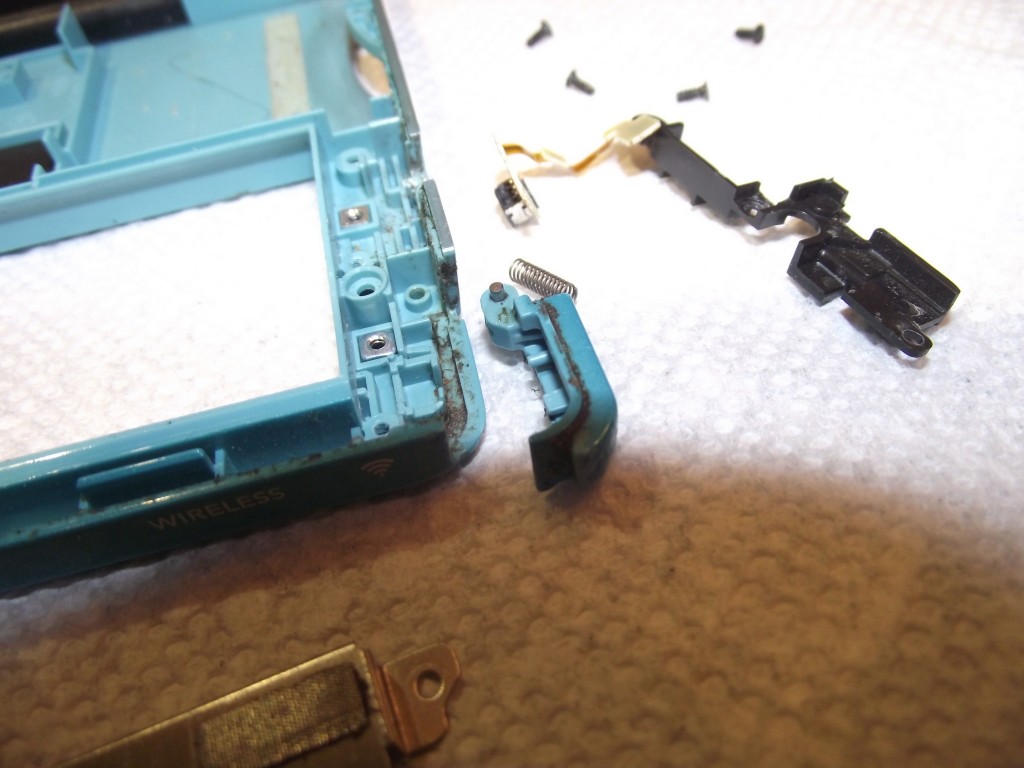

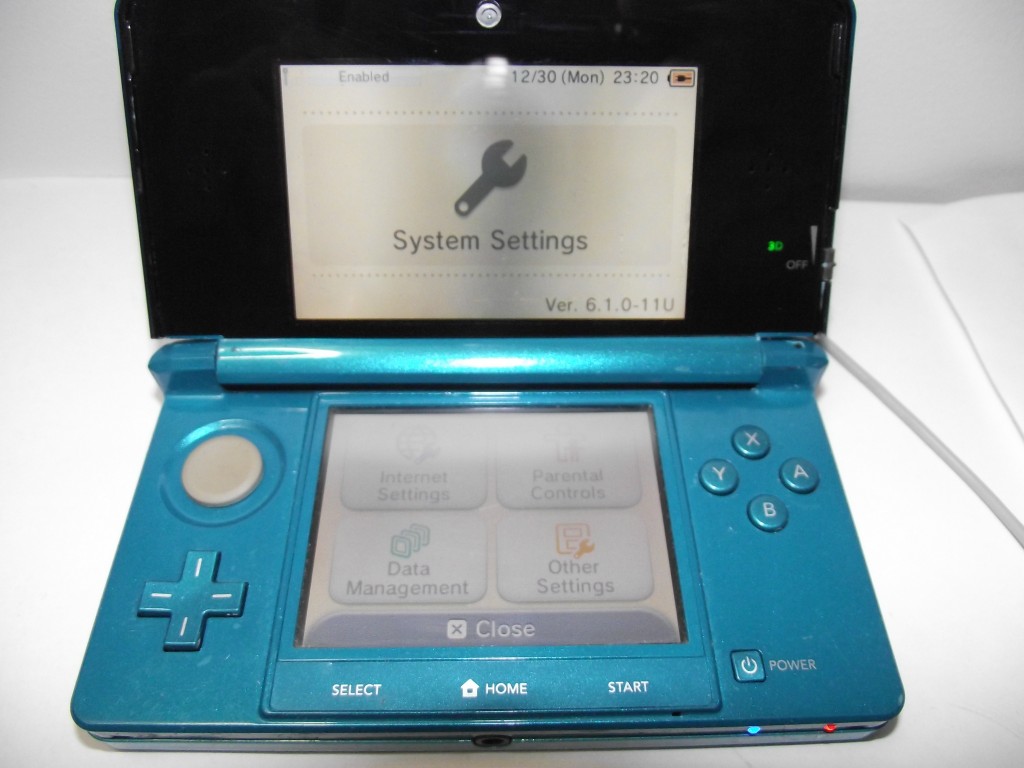

This serial number sticker is clearly a reproduction. So is the housing. But let’s not be hasty. We can’t conclude the whole thing is counterfeit. The seller did state, after all, that the entire housing may have been replaced as part of the refurbishment process. As long as the motherboard inside is genuine, we can’t say it’s a total scam. But first, there’s an important thing we mustn’t forget.

That’s odd. Why would the manual for a European model controller refer to “SCEA” (Sony Computer Entertainment America)? You’d think it would instead refer to SIEE (Sony Interactive Entertainment Europe) or just “SIE”, wouldn’t you? Additionally, it seems strange that a North American 1-800 phone number is listed as the support number for what’s ostensibly a product intended for the European market. I think at this point we have no choice but to open it and look inside.

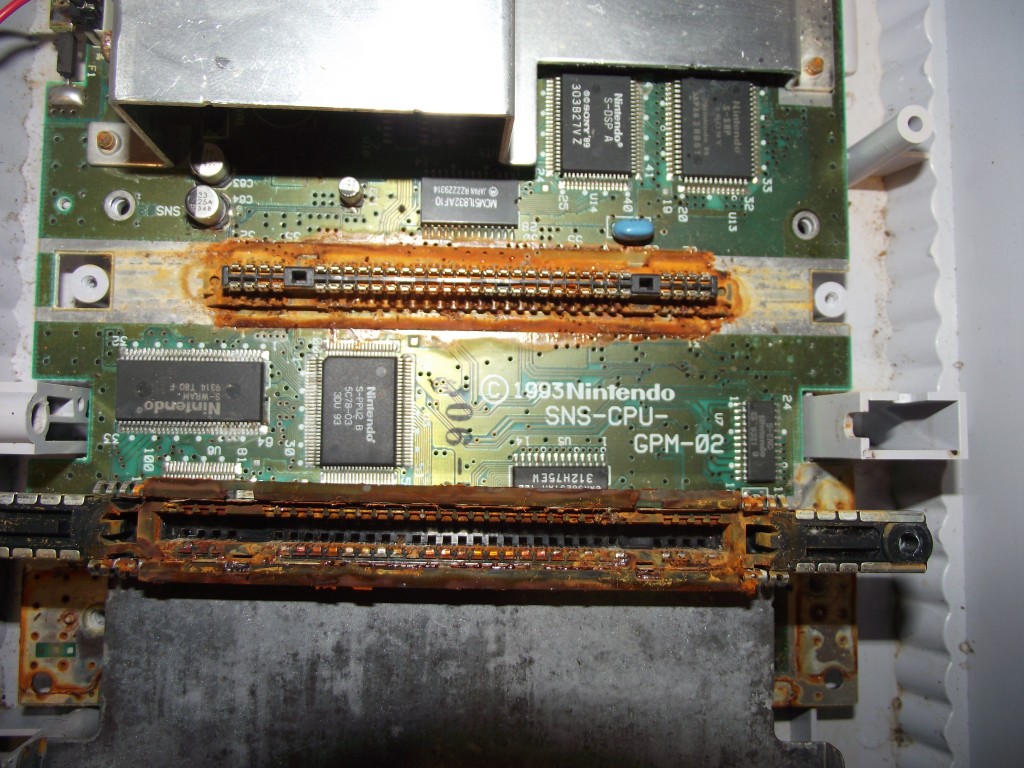

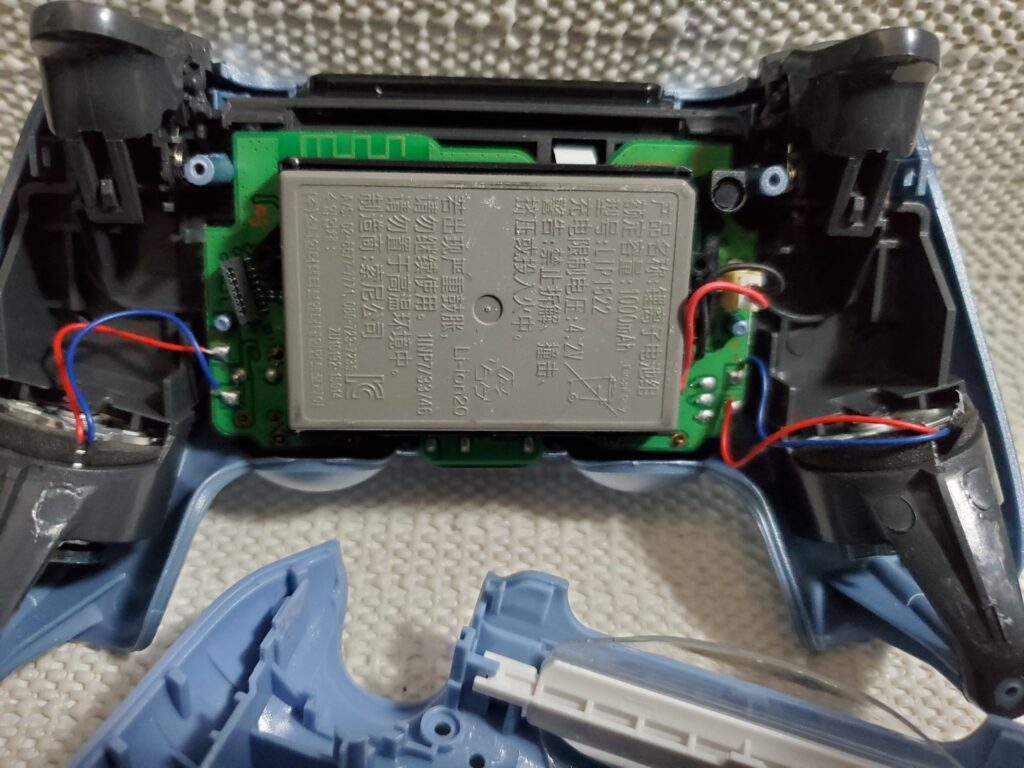

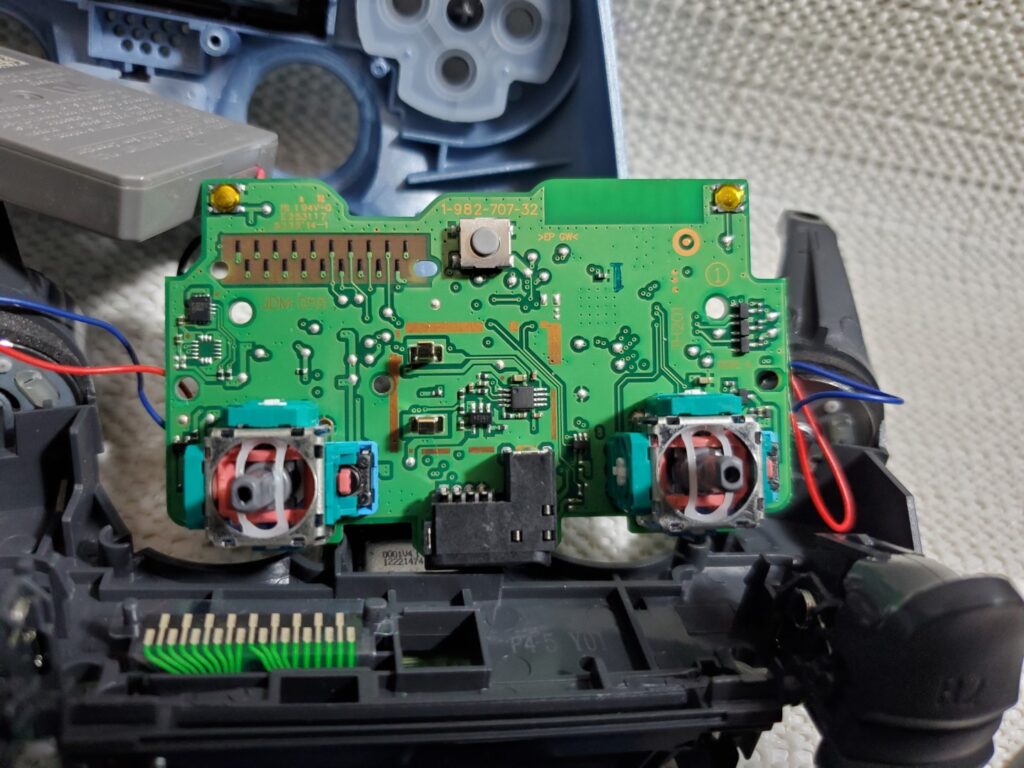

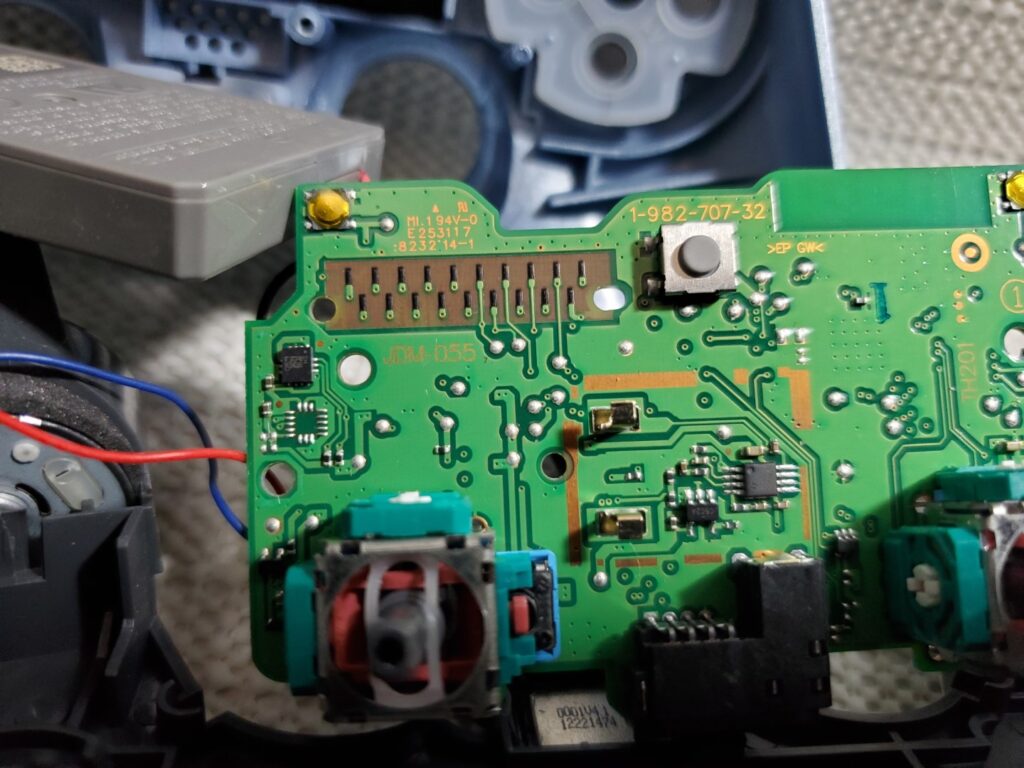

Oh dear. This is a puzzlement. It looks like a genuine battery, but the rest is fake.

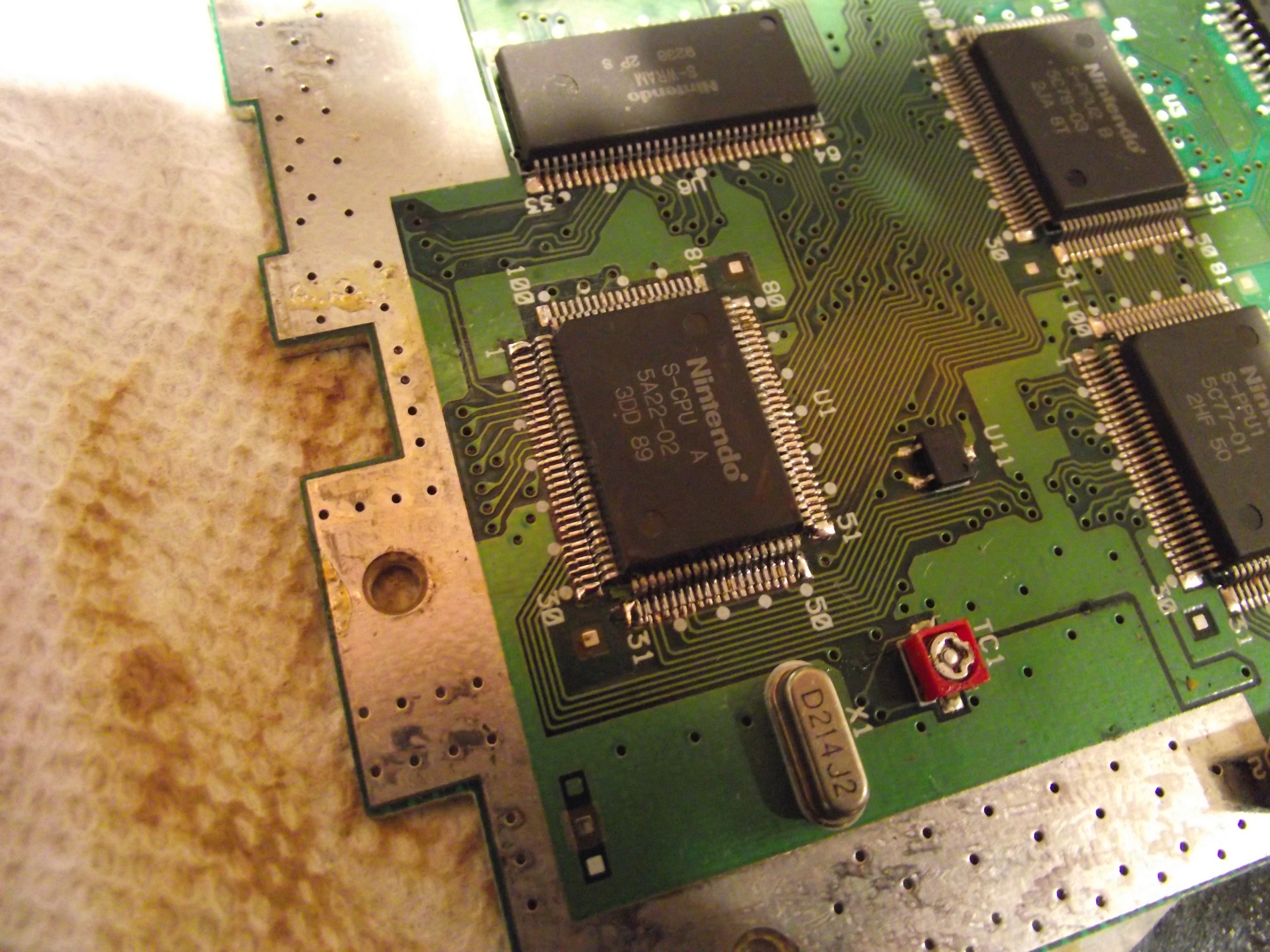

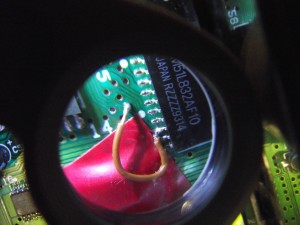

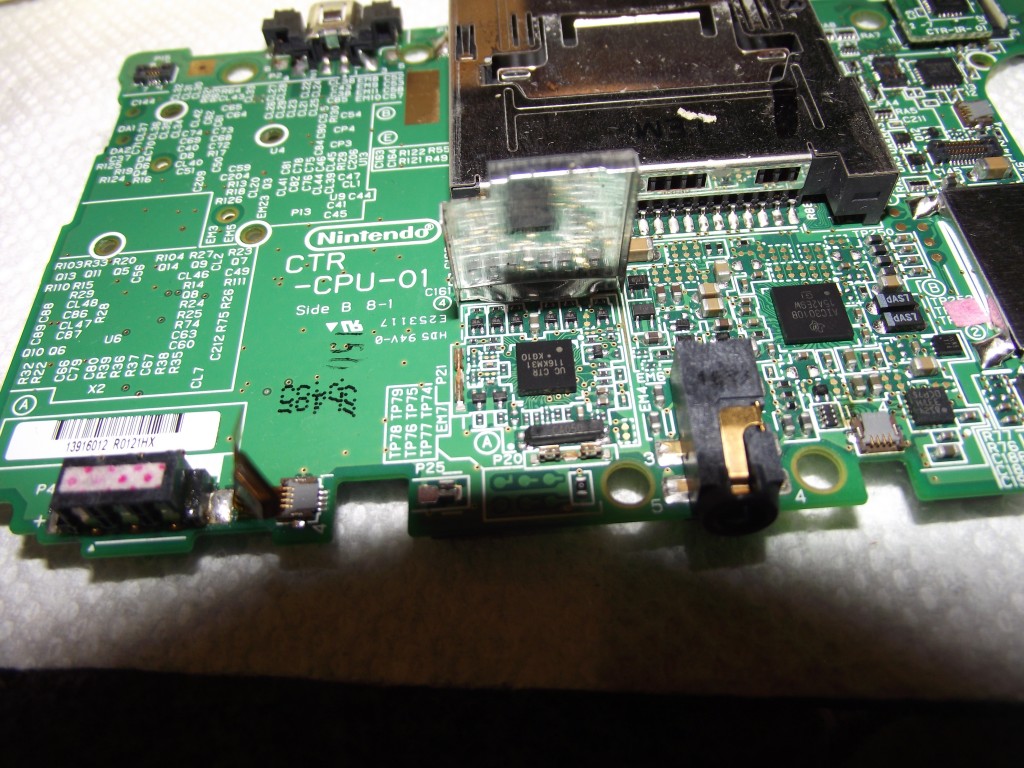

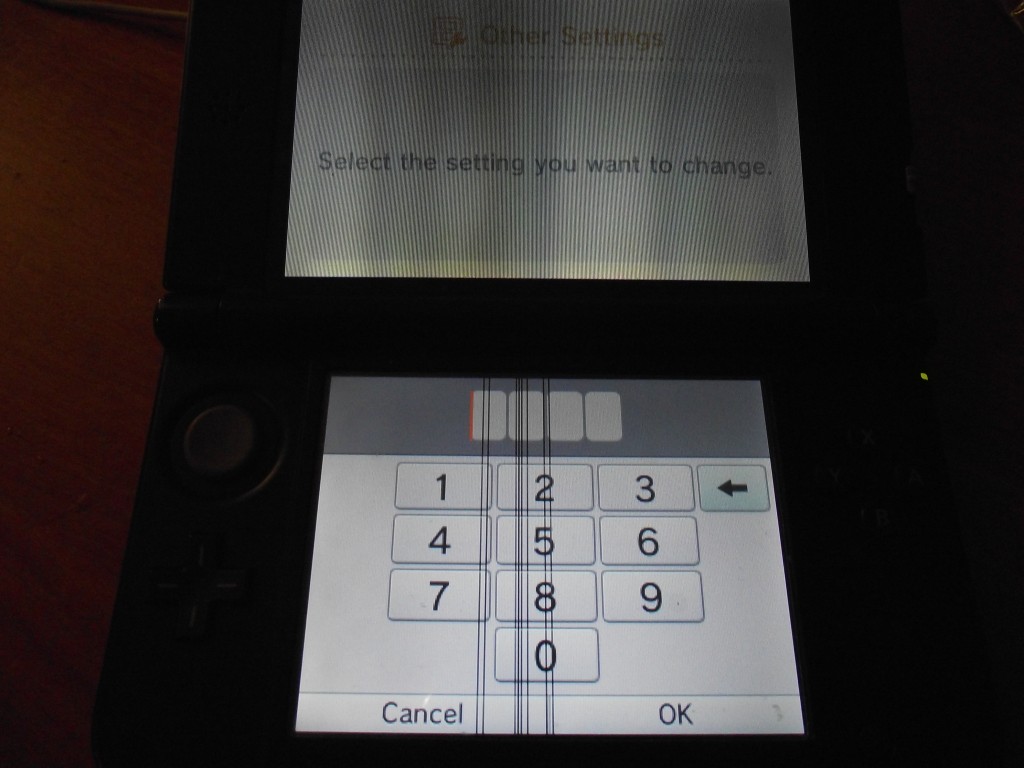

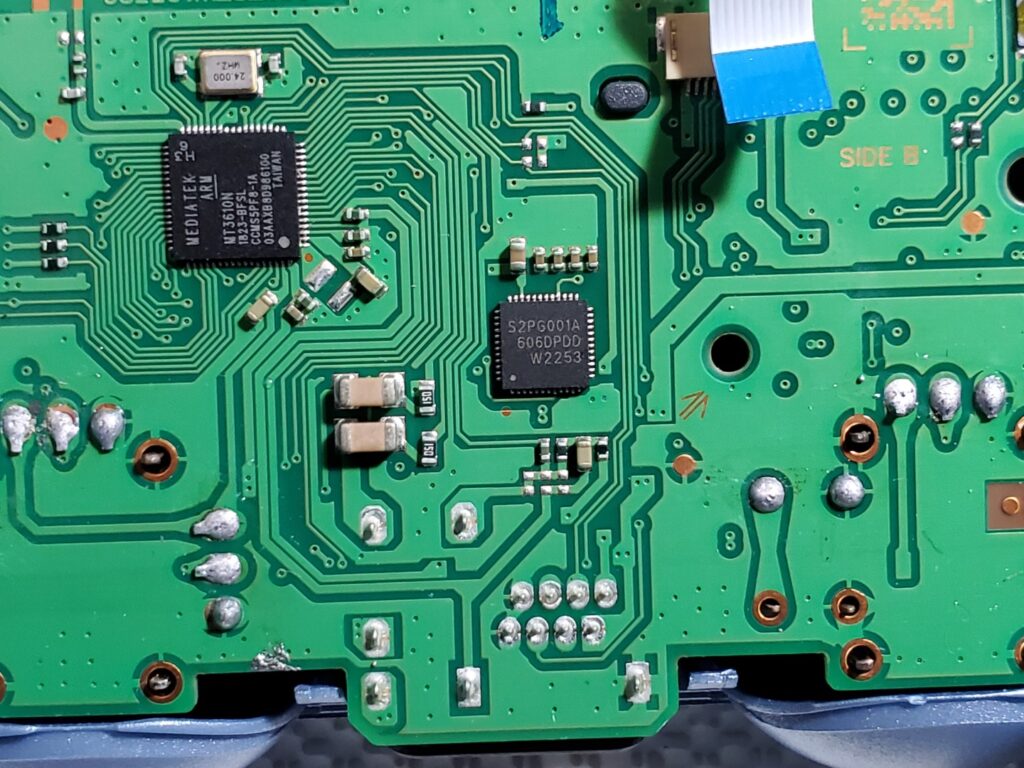

S2PG001A is actually the correct part number for the PMIC on JDM-055 controllers. But this doesn’t appear to be a genuine one. Neither does the MediaTek MT3610N. They both have the wrong numbers of pins. But on this topic I’m no expert. So I could be wrong about that. I suppose it may be possible the MT3610N could come in more than one package size. All I can say for sure is that genuine PS4 controllers don’t use chips that look like these. Also, unrelated to the questionable chips, get a load of the stray bits of solder smeared on the board near the lower left of the photo. That’s sloppy work.

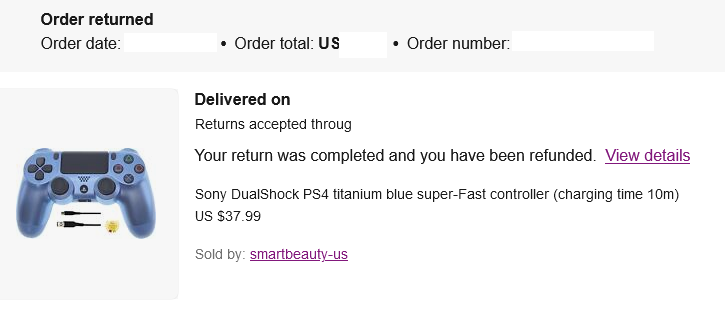

Well that was interesting. Now that we’ve had our fun, let’s return the controller for a refund. The listing stated all returns are accepted for 30 days, even remorse returns. So we’ve got no reason to feel bad about returning it. I’ll just open that return, print a shipping label, and drop it in the mail.

Great it was delivered. Now let’s check for that refund.

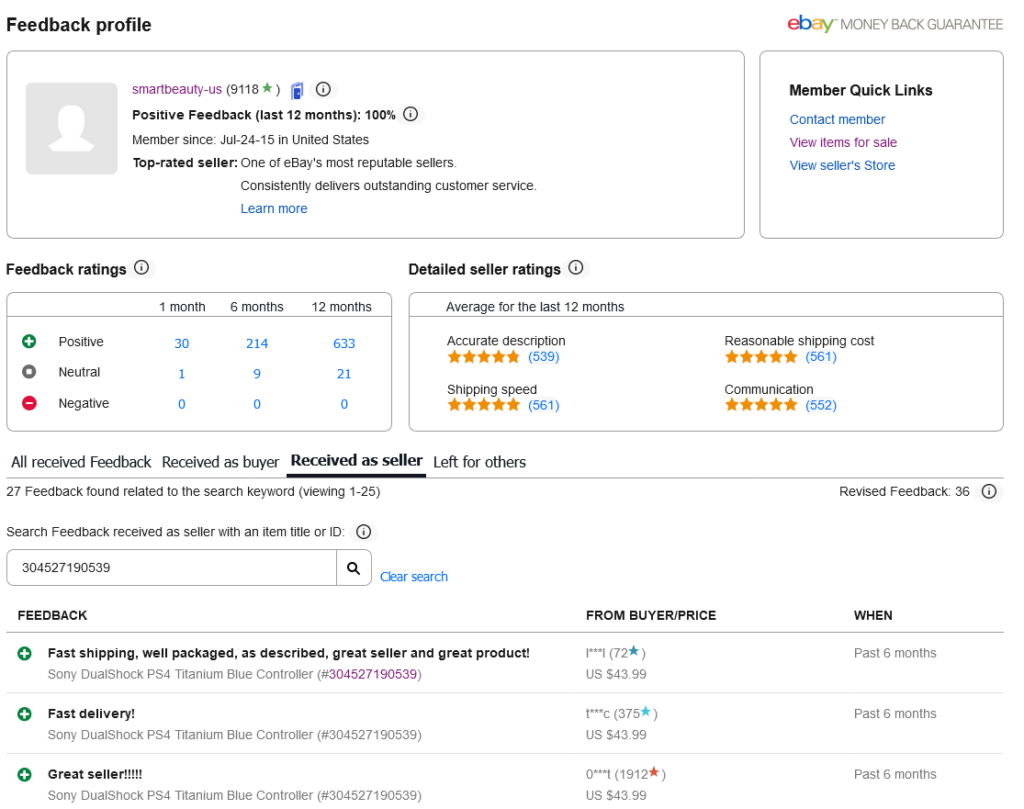

The only remaining task is to warn others about this scam through appropriate feedback. Let’s be sure not to mention the return request or anything else in our feedback comment that violates eBay feedback policies and could cause our comment to be deleted.

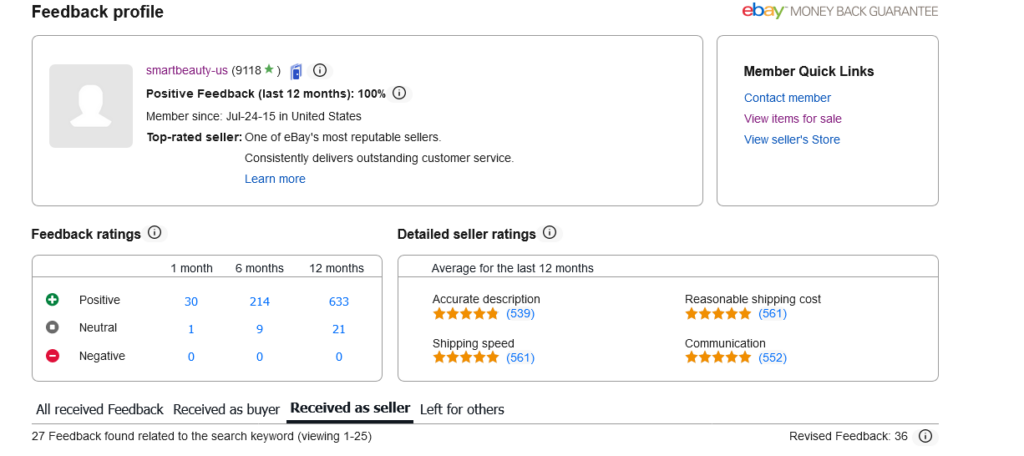

I don’t think you need a tinfoil hat to see that eBay simply doesn’t care that their so-called “experts” are just hawking fakes. The stock images this particular seller uses are nice and clean. They claim the items are “refurbished” and the fact they’ve been graced with the “eBay Refurbished” badge with its “One- or two-year warranty” and all its BS wankery about “vetted sellers” and “Multi-point inspections” means buyers have little reason to be suspicious. Plus the account is registered in the U.S. Buyers may be skeptical of similar listings that ship from China, but both the ship-from location and the seller’s account are U.S.-based. So there are few red flags for buyers to be wary of, other than the stilted English used in the listing text.

For the record, I have no problems whatsoever with generic controllers or other products made by third-parties. 8BitDo, for example, make some great controllers and sell and market them both legally and ethically. Companies like them are to be commended. What I have a problem with are scumbag sellers who deliberately scam consumers by intentionally describing a product as genuine and then sending a counterfeit instead. Of course, that’s been going on forever. But the twist here is that now eBay are actually assisting these people more blatantly than ever before.

I didn’t think to get screenshots before they were removed, but as I was waiting for the controller to arrive I witnessed several more buyers leave negative feedback for the seller, saying they received fake controllers. By the time I received my order though those negative comments had all been removed by eBay. So there’s no doubt eBay is complicit in this and are doing everything they can to protect their anointed sellers in the “eBay Refurbished” program, international intellectual property laws be damned.